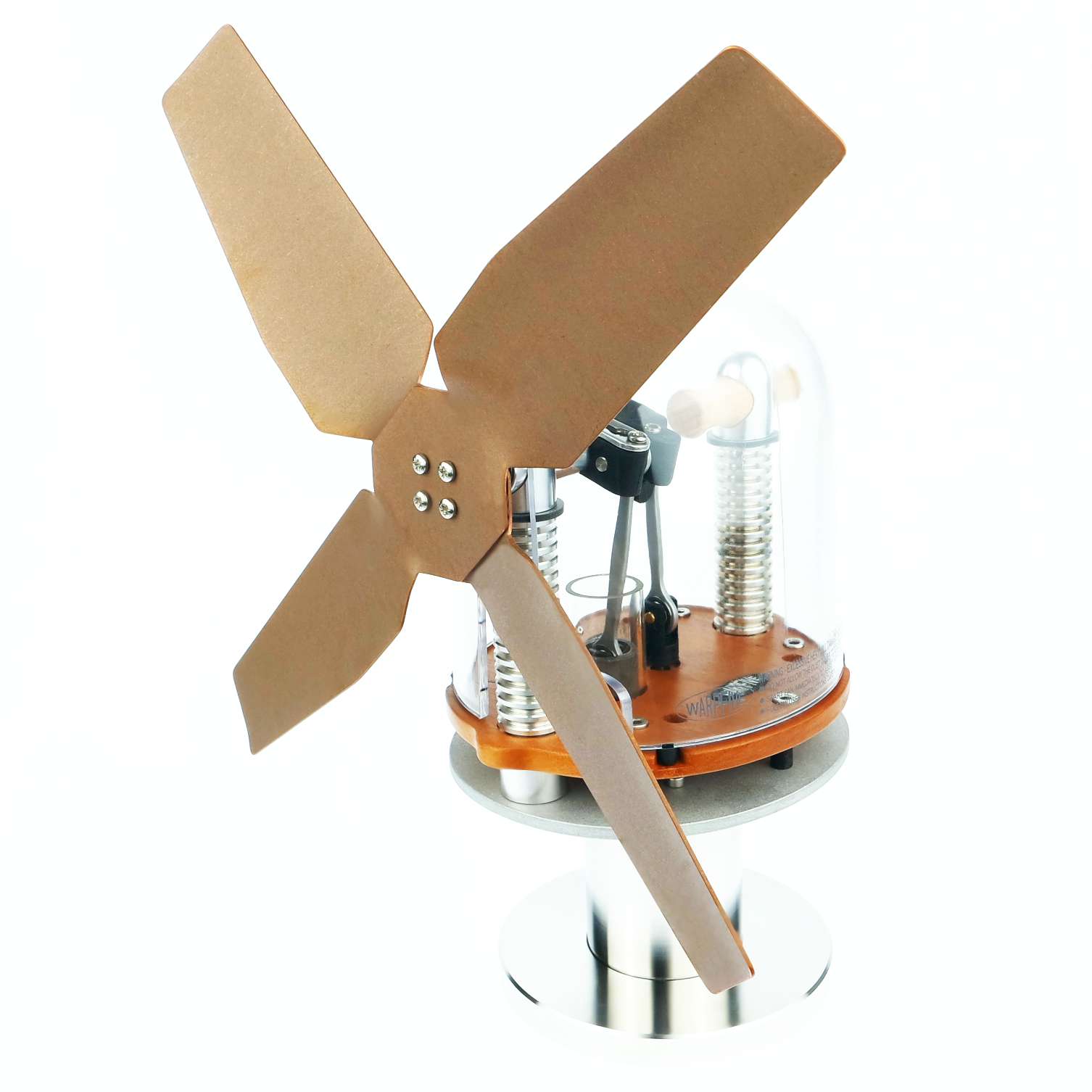

STIRLING ENGINE

STOVE FANS

Burn Less. Spread More Heat.

Shop By Category

Warpfive Fans – British Manufacturer

Warpfive Fans™ manufacture a range of eco-friendly products for use in your home.

Every product is designed to combine classic elegance with engineering excellence.

We aim to create beautiful products which you can enjoy and admire for a lifetime.

Explore the craftsmanship of Warpfive Fans, offering precision-made Stirling engines and home decor products, all meticulously handbuilt in the UK.

Discover the difference with a Stirling engine stove fan. By placing it on your wood burner you’ll enhance fuel efficiency, distribute heat evenly, and save money on heating bills. A Warpfive stove fan will quietly circulate warmth from your wood stove, plus heat up your space faster and more efficiently.

Our range of home decor products includes collectible Stirling engine fans powered by an ethanol burner or tealight candle plus other charming items like the Warpfive Whirligig and Fantascope models.

For precise temperature monitoring, trust our stove top thermometers. These accurate instruments provide reliable readings, ensuring your space stays comfortably heated.

Whether for yourself or as a special gift, choose Warpfive Fans for efficiency and style.

Our products add a touch of elegance and functionality to any space.

How do Stirling Engines work?

Stirling engines use heat to work. They do not require any electricity and they do not have any electrical components in their construction.

Stirling engines are purely mechanical and will run on any heated surface such as a log burner or an alcohol burner or even above a tea light candle.

Stirling engines work by moving a sealed volume of air from the a hot base to a cool top plate. The air is rapidly heated and cooled as it moves from the cool top plate to the hot base. The warm air expands and causes the piston to push up. While the cool top plate rapidly cools the air and causes it to contract. This results in a vacuum which pulls the piston down. The same volume of air is rapidly heated and cooled many times per second, extracting energy for the engine to work.

Stirling engines operate quietly (typically 12dB) which makes them highly desirable for certain applications. While they require great precision to build, you will be rewarded with exceptional reliability, power and longevity.

Warpfive Fans are silent miniature Stirling engines which use mechanical power to rotate a fan blade. Not only will you be fascinated by their distinctive appearance, you will also enjoy excellent Stirling engine performance.